Accelerating this process isn’t just a time saver, but a way to swiftly translate ideas into tangible prototypes. Join us in exploring essential tips to optimize each step of this process, from conception to materialization, aiming to expedite the prototyping of your project.

Tips to Speed up the Silicone 3D Printing Prototyping Process

Use Suitable Computer-Aided Design (CAD) Software to Accelerate the Design Process

We recommend using these software tools to assess the feasibility of your prototype. Specific design software speeds up project conception, significantly reducing the number of physical iterations required. These tools also facilitate collaboration and protot ype sharing, simplifying the transition from design to production.

Optimize Model Design

The success of your silicone prototype begins in the software design phase. As mentioned earlier, we recommend optimizing the model for physical printing by:

- Removing unnecessary details,

- Ensuring adequate wall thickness,

- Minimizing the use of support structures,

- Reducing overhangs,

- Creating flat support surfaces,

- Employing appropriate tolerances.

Choose the Right Silicone for the Desired 3D Prototype Type

The choice of silicone for a 3D prototype determines its characteristics and performance. It’s crucial to select silicone suitable for your application, considering factors such as its hardness.

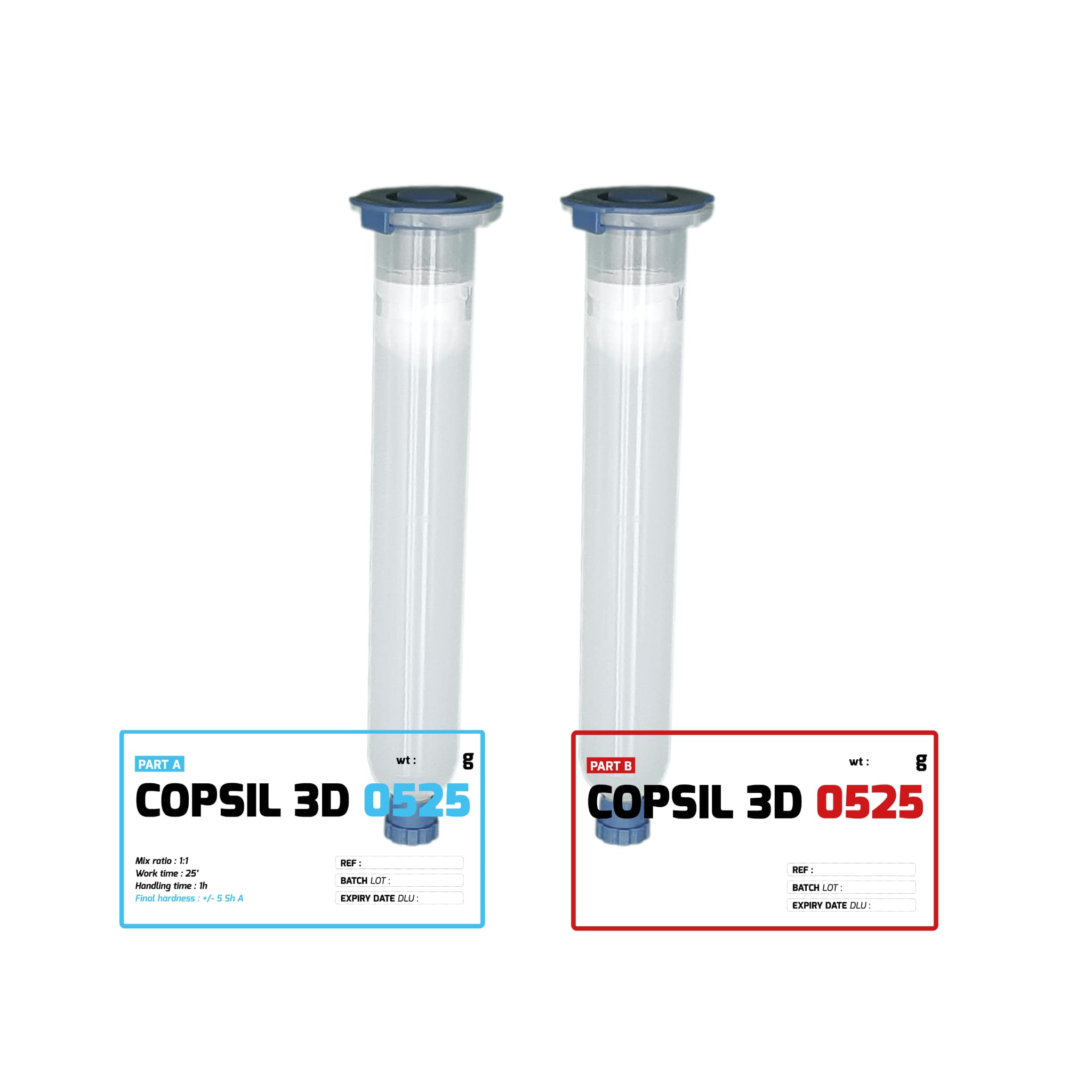

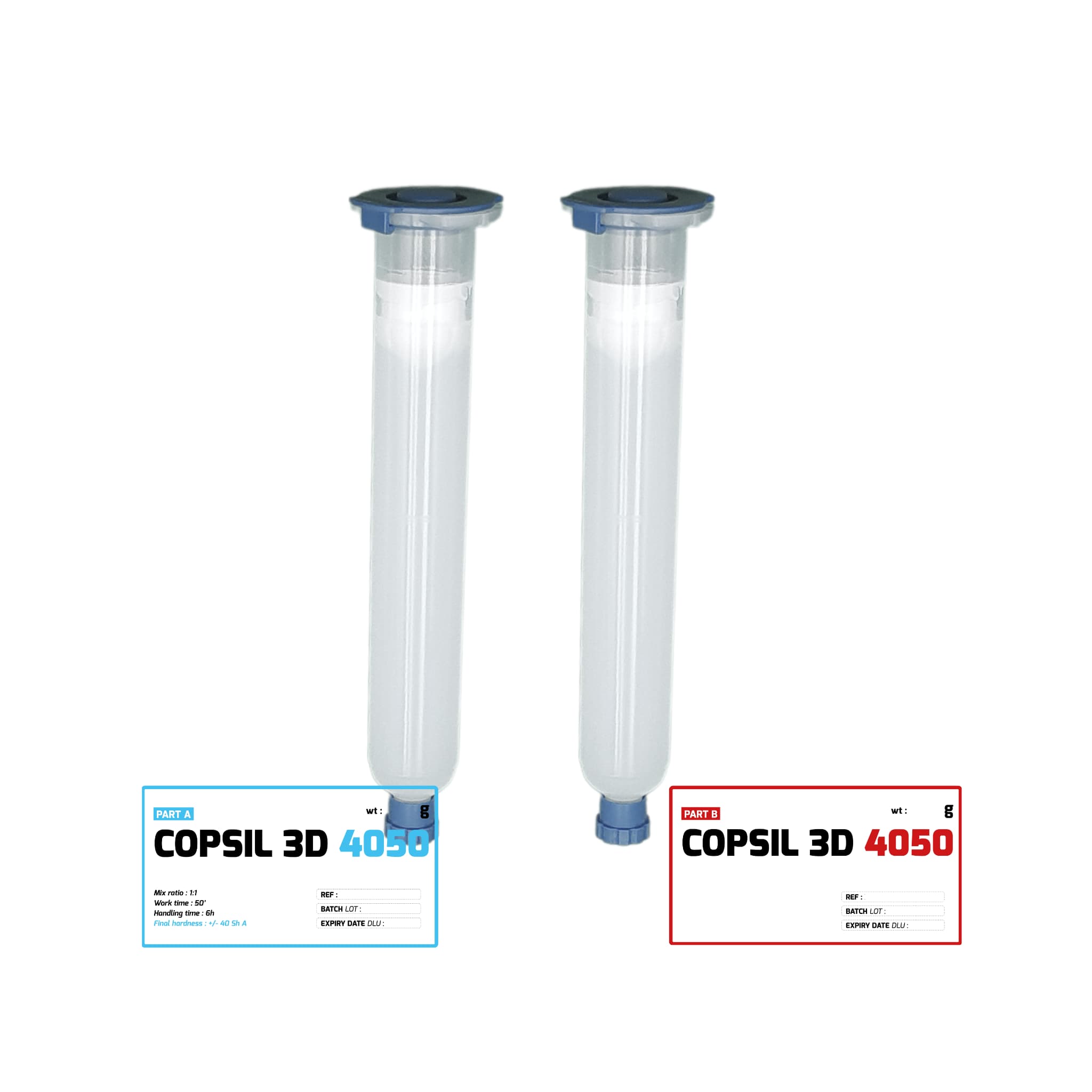

At COP, we’ve developed a range of RTV-2 silicone elastomers dedicated to 3D printing. This range offers four hardness levels: 5, 10, 25, and 40 ShA. Customized 3D printing silicone development is also a possibility.

Use an Adapted and High-Speed 3D Printer

Using a machine specifically calibrated and designed for silicone 3D printing significantly simplifies the process. Silicone 3D printing requires specific features such as the ability to extrude and handle flexible and viscous materials, specialized extrusion systems, or software tailored to the material.

In our laboratory, we utilize our partner Lynxter’s printer, the S600D, enabling the creation of RTV-2 silicone prototypes. Their new S300X printer allows printing of medical and industrial-grade silicones and utilizes integrated support printing technology for even more complex geometries.

Consider Hiring a Service Provider

To hasten the prototyping of silicone elastomer parts through 3D printing, expertise and appropriate resources are crucial. Discover our customized materials and printing service tailored to meet your specific needs: Prototypage 3D silicone.

Find out more : How does COP support you in developing your silicone 3D prototypes?

By adopting the outlined recommendations, from using suitable design software to selecting the right silicone and employing a dedicated printer, you can streamline the design of your 3D prototype and simplify its printing. This will not only reduce printing issues but also enhance the final prototype’s quality while optimizing your prototyping process’s efficiency.