We offer to print your proof of concepts (POCs) and prototypes using our range of printable silicones: COPSIL 3D.

This range is available in four hardness levels:

Why choose COP for your 3D silicone prototypes?

With over 35 years of experience in silicone chemistry and expertise in silicone additive manufacturing we help you save time and manage your budget effectively during the early stages of your prototyping project (POC, shape validation, no-mold R&D iterations)We relieve you of the technical and logistical constraints associated with 3D printing.

We operate a LYNXTER S600D printing machine equipped with an LIQ21 toolhead capable of depositing two-component liquids in the form of regular cords. The machine’s advantages lies in its ability to print large-sized parts with a capacity of 390×600 mm.

- Quick and easy delivery of your proof of concept

- Access to cutting-edge technology to produce functional pure silicone prototypes

- Validation of the effectiveness of the silicone printing method before integration into your equipment

3D Printing Service for Silicone Prototype

Specify your request and send your STL file using a file transfer service to get in touch with a sales representative regarding your 3D silicone prototyping project.

- 4 hardness levels available: 5, 10, 25, and 40 ShA

- Prototyping and small-batch manufacturing

- Free quote

Our service covers printing only, prototyping remains within the client’s expertise

Our 3D Printing Solutions

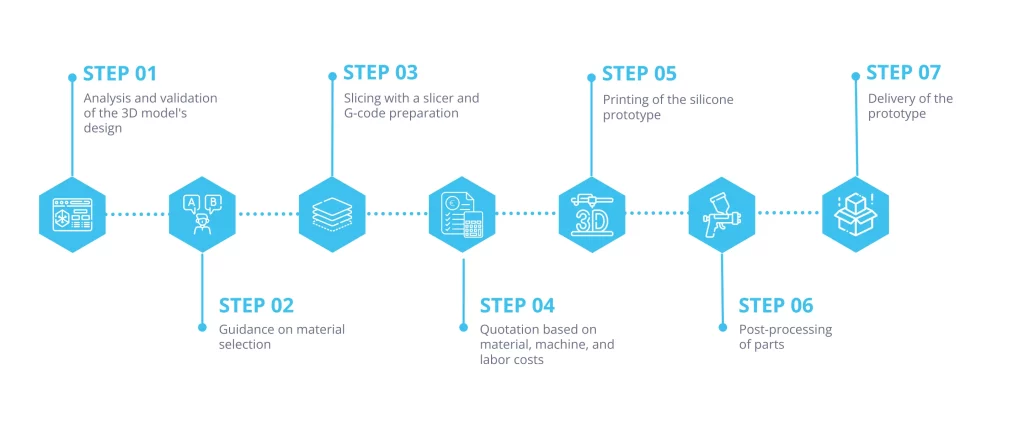

The major steps of Silicone 3D Prototyping at COP

Our Materials and Technologies Offering

We’ve developed a range of RTV-2 silicone elastomers in four hardness levels: 5, 10, 25, and 40 ShA. These skin-contact silicones are designed for manufacturing flexible parts.

Do your prototypes involve complex geometries? With COPSIL 3D ADD-GEL support gel, we can produce silicone prototypes with intricate structures (overhangs of more than 45° and bridges of over 5 mm).

COPSIL 3D 0525

Soft skin contact RTV-2 silicone for additive manufacturing

- 05 Shore A, translucent printable material

- Working time : 25 min

- Removal from mold : 1 h

The COPSIL 3D range is designed for the manufacture of flexible parts with complex design or small series production (prototyping). Printed silicone elastomers have mechanical characteristics at least equivalent to parts made by casting or injection.

Product suitable for skin contact applications according to ISO 10993-5

COPSIL 3D 1025

Low hardness skin contact RTV-2 silicone for additive manufacturing

- 10 Shore A, translucent printable material

- Working time : 25 min

- Removal from mold : 1 h

The COPSIL 3D range is designed for the manufacture of flexible parts with complex design or small series production (prototyping). Printed silicone elastomers have mechanical characteristics at least equivalent to parts made by casting or injection.

Product suitable for skin contact applications according to ISO 10993-5

COPSIL 3D 2525

Medium hardness skin contact RTV-2 silicone for additive manufacturing

- 25 Shore A, translucent printable material

- Working time : 25 min

- Removal from mold : 1 h

The COPSIL 3D range is designed for the manufacture of flexible parts with complex design or small series production (prototyping). Printed silicone elastomers have mechanical characteristics at least equivalent to parts made by casting or injection.

Product suitable for skin contact applications according to ISO 10993-5

COPSIL 3D 4025

Firm skin contact RTV-2 silicone for additive manufacturing

- 40 Shore A, translucent printable material

- Working time : 25 min

- Removal from mold : 1 h

The COPSIL 3D range is designed for the manufacture of flexible parts with complex design or small series production (prototyping). Printed silicone elastomers have mechanical characteristics at least equivalent to parts made by casting or injection.

Product suitable for skin contact applications according to ISO 10993-5

COPSIL 3D 4050

Firm skin contact RTV-2 silicone for additive manufacturing

- 40 Shore A, translucent printable material

- Working time : 50 min

- Removal from mold : 1 h 30

The COPSIL 3D range is designed for the manufacture of flexible parts with complex design or small series production (prototyping). Printed silicone elastomers have mechanical characteristics at least equivalent to parts made by casting or injection.

Product suitable for skin contact applications according to ISO 10993-5

COPSIL 3D ADD-GEL

COPSIL 3D® ADD-GEL is a support for RTV-2 liquid silicone printing, allowing the realization of complex parts with important bridges or overhangs. The extrusion of liquid silicone takes place within the gel that supports the printed part. It is ready to use, non-toxic and sinkable.